The Hidden Danger in Stone Fabrication: Understanding Crystalline Silica and Safer Alternatives

Natural stone countertops, flooring, and wall cladding possess undeniable beauty. For centuries, people have prized materials like granite, marble, and quartzite for their unique aesthetics and durability. However, behind this natural allure lies a potential health risk for the professionals who bring these surfaces to life: crystalline silica.

What is Crystalline Silica?

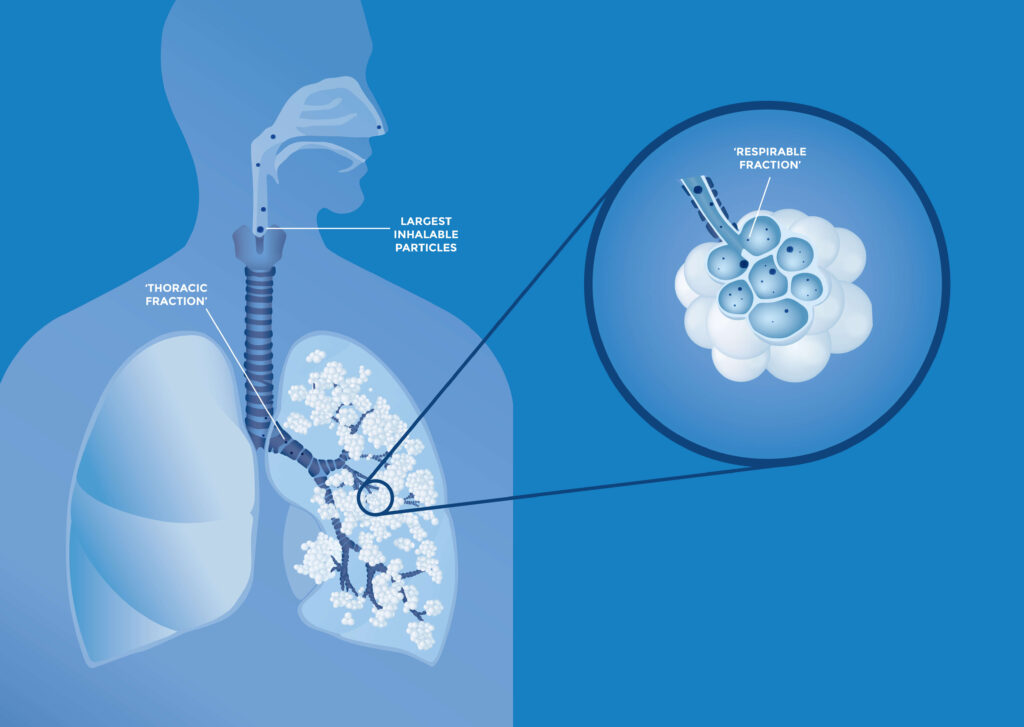

Crystalline silica is a naturally occurring mineral found in many types of rock, sand, and soil. The process of cutting, grinding, or polishing these materials releases tiny particles of silica dust into the air. Because these microscopic particles are so small, people easily inhale them, and they lodge deep within the lungs.

The Serious Health Risks of Silica Dust

Over prolonged exposure, inhaling crystalline silica dust can lead to severe and irreversible respiratory diseases, including:

- Silicosis: A scarring of the lung tissue that makes it difficult to breathe. There is no cure for silicosis, and it can be progressive and even fatal.

- Lung Cancer: Studies have linked occupational exposure to crystalline silica with an increased risk of developing lung cancer.

- Chronic Obstructive Pulmonary Disease (COPD): Long-term exposure can contribute to the development of COPD, a group of lung diseases that block airflow and make breathing difficult.

- Kidney Disease and Autoimmune Diseases: Emerging research also suggests a link between silica exposure and an increased risk of kidney disease and certain autoimmune disorders.

The Importance of Safety Measures

For professionals in the stone fabrication industry, understanding these risks is paramount. It is absolutely crucial to implement stringent safety measures to minimize exposure to silica dust. This includes:

- Education and Training: Comprehensive training on the hazards of silica dust and proper safety protocols.

- Personal Protective Equipment (PPE): Consistent and correct use of respirators that are NIOSH-certified to protect against silica dust.

- Engineering Controls: Implementing dust extraction systems, wet cutting techniques, and ventilation to capture and remove silica dust at its source.

- Regular Monitoring: Air quality monitoring to ensure that exposure levels are within safe limits.

A Preventable Tragedy: The CDC’s Findings

The Centers for Disease Control and Prevention (CDC) has clearly stated that silicosis is a preventable disease. Despite this clear statement, tragically, cases continue to emerge in the United States among workers in stone fabrication and other industries. Consequently, this stark reality underscores the urgent need for ongoing awareness, education, and the consistent implementation of effective dust control measures.

Mineral Surfaces: A Breath of Fresh Air Through Innovation

In contrast to natural stone, Mineral Surfaces – such as sintered stone, porcelain slabs, and ultra-compact surfaces – are engineered with a significant advantage: their near-zero crystalline silica content. The manufacturing process for these materials carefully selects and fuses minerals without the high levels of silica found in natural stone. This innovative approach dramatically reduces the amount of hazardous silica dust generated during fabrication, creating a much safer working environment for the professionals who handle them.

Prioritizing Health in Surface Fabrication

While the natural beauty of stone is undeniable, the health risks associated with silica exposure during fabrication cannot be ignored. By understanding these risks and embracing innovative alternatives like Mineral Surfaces, we can prioritize the health and well-being of the skilled professionals who bring our design visions to life.

Learn More: